Pet food is a growing market, demand for almost every year on the increase.Appropriate big offer from the complete solution in the packaging.Each machine is precision manufacturing, provides the high quality for the pet feed and food production machinery.

Should be a big twin screw extrusion machine has won international patent, in the puffing process, add steam (mechanical) can use lower SME production of particles.In pet food production line, appropriate USES vertical drum dryer, accurately control temperature, the grain moisture after drying high evenness, hierarchical design can quickly replace the product.

Appropriate process design and equipment features and advantages

To meet customer demand design concept is appropriate big goal all along, we realize the customer in the face of the raw material prices, under the pressure of rising costs and labor costs, energy consumption is still the pursuit of quality products which conform to the market competition, the appropriate design concept is to continuously improve, improve the process and equipment, let the customer get the best profits, we through the following description, show us how to reach the goal of customer satisfaction.

Pet food security is appropriate large biaxial paddle mixer key features.Appropriate large mixer ensures that the mixture of high precision and health characteristics, such as minimizing remains and the bacterial growth.Appropriate mixing machine has been sold to many countries, including Japan, the Netherlands, South Korea, China, Thailand, India, Taiwan, etc.

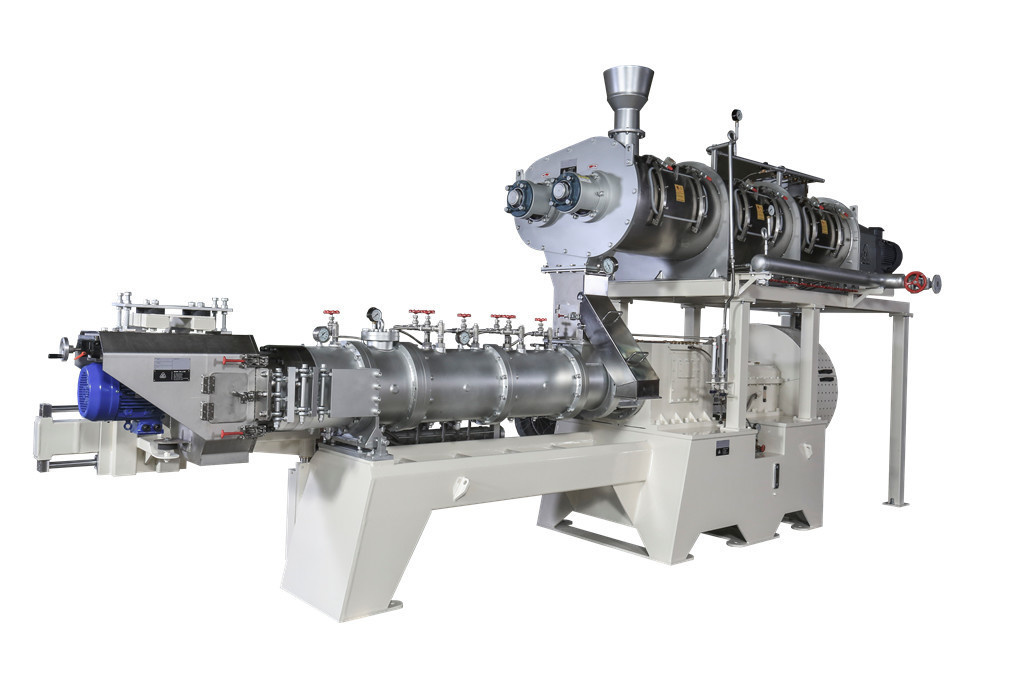

Should have a wide range of puffing system, can produce different shape, texture and color of pet food.It contains the expansion type, high moisture, soft and filling particles.Appropriate big provide single shaft extrusion machine and two bulking systems ContraTwin reverse twin screw extrusion machine.

ContraTwin reverse twin screw extrusion machine in improving the quality of production quantity (especially when running high fiber formula), reduce energy costs and reduce the wear and tear cost, outstanding performance.Our reverse twin screw extrusion machine provide very large delivery pressure inside the casing, enable us to produce high meat content at a speed of others find it hard to believe that the particles and filling products.

Compared to the general vertical box type dryer, appropriate large vertical cylindrical dryer cover an area of an area small, and the use of power is much less than in most of the dryer, which reduces the noise, energy costs and maintenance costs.Drum dryer specially designed to prevent internal air flow is very uniform, thus indiscriminate drying operations of product.The air can make the products not too dry.Will be dried products are roll (up to seven times) can achieve the best effect of evaporation evenly.